Low Hydrogen Electrode E7018

The Low Hydrogen Electrode E7018 is engineered for high-strength welding on carbon steel and low-alloy steel structures. Its low-hydrogen coating prevents porosity, cracking, and weld defects — making it the preferred electrode for critical and heavy-duty applications.

With excellent arc stability and superior mechanical strength, E7018 is trusted by fabrication shops, oil & gas contractors, and infrastructure projects across the UAE.

Key Advantages

- High tensile strength for heavy structures

- Minimal hydrogen content reduces weld cracking

- Excellent arc control & bead appearance

- Optimal performance on AC & DC+

- Moisture-resistant coating (storage compatible with quiver)

- Ideal for multipass welding in tough environments

Best-Suited Applications

- Structural steel fabrication

- Oil & gas pipeline work

- Heavy machinery builds & repairs

- Power plants and industrial projects

- Pressure vessels & tanks

- Shipbuilding & marine structures

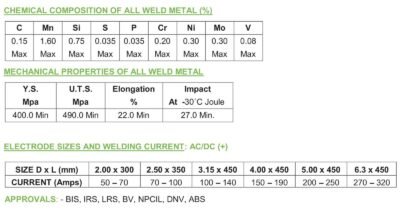

DESCRIPTION AND APPLICATIONS

SUPER-LH is a heavy coated low hydrogen iron Powder type electrode designed to weld heavy restrained joints subject to dynamic loading. Weld deposit is tough, ductile and is of RADIOGRAPHIC quality, deposition efficiency exceeds 115%. Typical applications include heavy structures subjected to dynamic loading and impact. Highly restrained joints, boilers and pressure vessels, atomic reactor shells, bridges, railway wagons and coaches, earth moving equipment etc.

Low Hydrogen Electrodes are specially designed welding electrodes that deliver superior mechanical properties, high strength, and excellent crack resistance. They are widely used for structural welding, pressure vessels, pipelines, and other heavy-duty applications where quality and durability are critical.At Gessco General Trading LLC, Dubai, UAE, we supply premium quality mild steel low hydrogen electrodes across the GCC and neighboring countries. Our products are sourced from trusted manufacturers, ensuring consistent performance, strong arc stability, and smooth weld finish.

Key Features

Low Hydrogen Content – Minimizes risk of hydrogen-induced cracking.

High Strength & Durability – Ideal for structural and pressure applications.

Smooth Arc Performance – Ensures stable welding and minimal spatter.

Excellent Mechanical Properties – Strong, tough, and impact-resistant welds.

Versatile Applications – Suitable for pipelines, boilers, storage tanks, bridges, and heavy fabrication.

Moisture Resistant – Coating reduces hydrogen pickup, ensuring weld integrity.

Applications

Shipbuilding and offshore structures

Oil & gas pipelines and refineries

Power plants and boiler fabrication

Pressure vessels and storage tanks

Heavy steel fabrication and repair